Scientists from Samara University and Samara State Medical University have developed and patented the device for testing aortic tissues. The data obtained with this device will help doctors predict in the near future the risk of aortic rupture and the need for surgery, as well as facilitate and improve selecting the implant when preparing a patient for surgery. The project has received financial support in the form of the grant from the Samara Region Innovation Fund.

The aorta is the main and largest artery in the human body. Through the aorta, oxygen-rich blood is transported from the heart to the rest of the internal organs. Due to various pathological factors, the inner wall of the aorta may begin to structurally change, dissect and stretch, resulting in forming a so-called aneurysm: the aortic wall enlarges forming a sac or a spindle, which can rupture over time, leading to death in 90% of cases. The aorta aneurysm and dissection usually develop at the age of 50 to 79 years, the disease frequency, according to statistics, is 3 cases per 100,000 women and 117 cases per 100,000 men per year. In the Samara Region, 200–250 people die annually because of the aorta aneurysm rupture.

“For preventing the aortic rupture in patients with aneurysm and dissection, preventive surgical intervention is the only way to save their lives. Timely and accurate identification of high-risk patients requires effective prognostic indicators of aortic adverse events and accurate thresholds for risk distribution. Our device is related to medical testing technology and makes it possible to create a standardized, universal method for determining the morphology and biomechanical properties of the aortic wall, based on the test results of biological tissue samples. This will provide doctors with an important additional prognostic indicator for assessing a particular patient’s aorta and comparing it with other risk factors. This will make it possible to create a program (scale) for predicting rupture or growth of the aorta in patients, based on a combination of factors, and offer patients timely surgical treatment before rupture. In other words, our device provides the data, using which doctors are already beginning to develop a universal system for determining biomechanical properties of the aorta and predicting development of an aneurysm and the risk of rupture”, said Yaroslav Erisov, Head of Samara University’s Department of Metal Forming.

Currently, doctors use the size of the aneurysm diameter as a criterion for the need for urgent surgical intervention. An asymptomatic aneurysm with its diameter of more than 5.5 cm in men and more than 5 cm in women is considered the indication for surgery. However, the decision on the surgery urgency, based only on the size of the diameter may be inaccurate: according to statistics, over half of aneurysms with a diameter of more than 5 cm remain completely stable for a long time, and about 13% of aneurysms with a diameter of less than 5 cm, on the contrary, have a significant risk of rupture and require immediate surgery.

“Although the size of the diameter is in practice the main indicator for making a decision on surgery; there are many different variables at the stages of determining the status of an aneurysm and predicting the risk of rupture: for example, the patient’s age and gender, lifestyle, hypertension, bad habits, concomitant diseases, because all patients are completely different, with various health conditions and lifestyles. Therefore, for understanding the process of the aneurysm development, it is very important to know the biomechanical properties of aortic tissue in a particular patient, depending on these variables – age, health condition, etc. The universal system being developed for determining properties of the aorta and predicting the aneurysm development will offer doctors additional criteria for prescribing surgery, based on the mathematical model. This will help, for example, save lives of those patients whose aneurysm diameter is still small, but there is a hidden risk of rupture”, noted Oleg Dmitriev, Head of the Vascular Surgery Department No. 1 at the Surgery Faculty Hospital of Samara State Medical University.

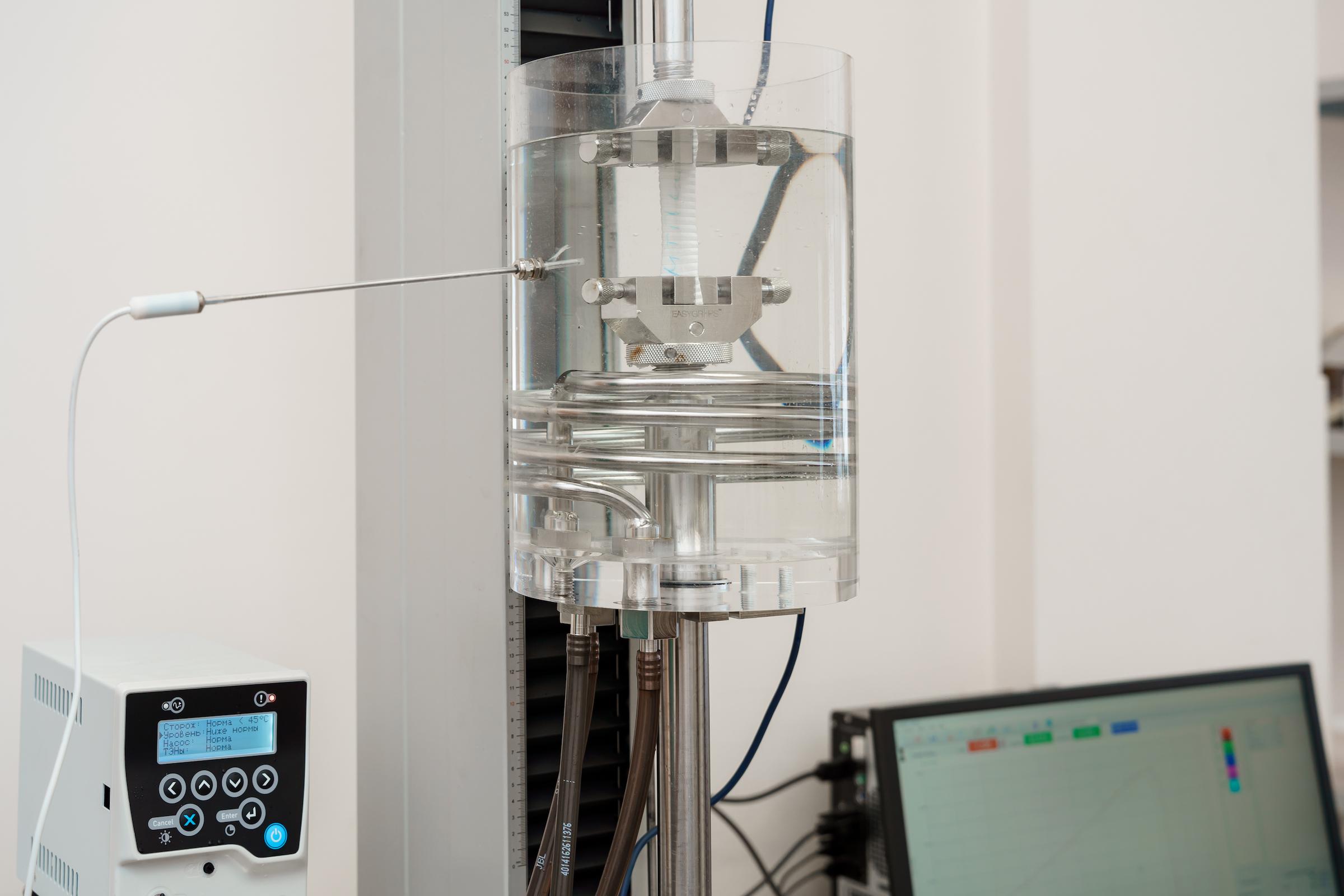

The testing device created by Samara scientists fits on an ordinary desk, but the size of the “subjects” is much smaller: these are small pieces of aortic tissue, up to 4 cm in length, removed earlier during surgical operations in various patients. By the nature of the “executions”, which these biomaterials are subjected to during the tests, the device can be roughly compared to a guillotine and a rack: first, a piece of aortic tissue is fixed on a catting platform and cut to the desired size with the vertically moving blade. Then the resulting test sample is fixed in the tooling and placed in the container with the solution having physical and chemical properties of human blood.

Next, the special tool exposes the piece of tissue to various loads, simulating those that are usually experienced by aortic tissues inside a person during the blood flow to pass. The test sample is stretched mercilessly in different planes, and the sensors of the device accurately record the stress and deformation of the tissue, depending on the loads applied. The specialists enter the obtained data on the biomechanical properties of the sample into the database and compare it with a set of personal data (age, gender, health condition, etc.) of the very patient who previously had this fragment of the aorta removed during surgery. This is the way how the basis for the future universal system for detecting biomechanical properties of the aorta and predicting the aneurysms development and the risk of rupture is being created. By the way, patents of the Russian Federation have already been issued for this device, as well as for the testing methodology developed by the scientists.

The test results on this device will also help doctors in the selection of implants, which are installed during operations in place of the aortic sections to be removed.

“For successful aortic surgery, it is very important to select the most suitable material for the implant. The choice of a particular material should be based on biomechanical properties and morphology of the aorta, which can vary greatly from patient to patient. Due to our project, it will be possible to significantly simplify the process of selecting the material for the implant, making it more personalized. The correct choice of material will help avoid possible postoperative complications, such as rupture and formation of repeated aneurysms”, emphasized Yaroslav Erisov.

It is expected that it may take about two years to create the universal system for detecting biomechanical properties of the aorta and predicting the aneurysm development.

Photo: Olesya Orina

RU

RU  EN

EN  CN

CN  ES

ES